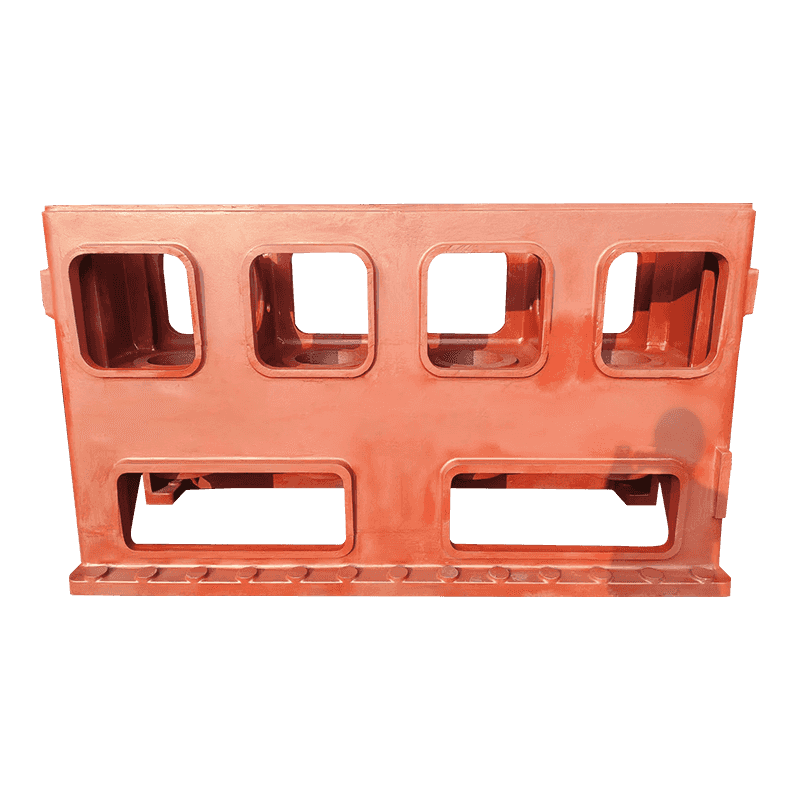

The rigidity of a machine tool column is paramount in ensuring consistent machining accuracy. A column with high structural strength resists deflection and flexing under varying load conditions, providing a stable platform for all machine movements. This resistance to deformation minimizes undesirable variations in tool position during cutting operations. As cutting forces are applied, the column's rigidity directly prevents the machine from shifting, which could otherwise induce unwanted errors such as dimensional deviations, surface roughness, or misalignment. Essentially, a rigid column stabilizes the entire machine, ensuring that the cutting tool stays precisely in its intended path, thereby improving accuracy and repeatability of each operation. By supporting heavy-duty and precision workpieces without flexing, the column ensures that the overall geometry of the part being machined stays true to design specifications.

In machining, vibrations can arise from multiple sources: cutting forces, the machine's movement, and even external environmental conditions. A well-designed machine tool column with high inherent damping properties absorbs and dissipates these vibrations, preventing them from propagating through the rest of the machine. Materials with natural damping characteristics, such as cast iron or composite materials, are commonly employed in the construction of machine tool columns because they can absorb vibrational energy efficiently. These materials dissipate kinetic energy before it can be transmitted to the moving parts of the machine, such as the tool spindle or the workpiece holder. This reduction in vibrational energy leads to improved cutting performance, finer surface finishes, and, most importantly, greater accuracy during the machining process.

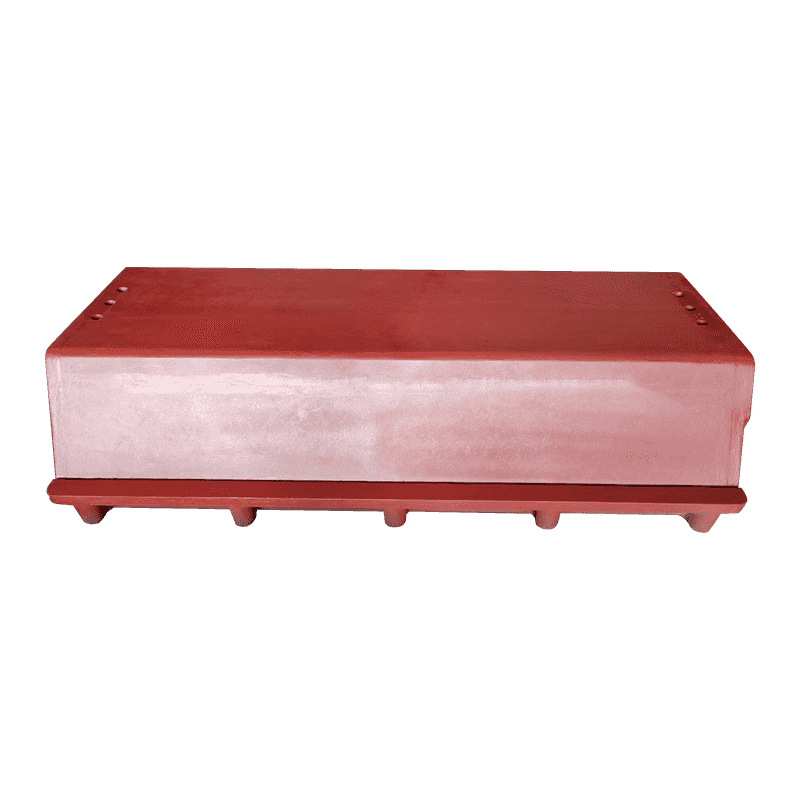

The mass of the machine tool column is another critical factor in mitigating vibrations. A heavy column possesses significant inertia, which enables it to resist changes in motion, including vibrations and oscillations caused by the cutting process. The larger the mass of the column, the greater the resistance it offers to high-frequency vibrations that could otherwise disturb the machining process. This added weight helps stabilize the machine tool under heavy loads, preventing unwanted shifts in the machine’s position and minimizing the potential for dimensional errors. For high-speed or high-precision machining applications, a machine tool column with a higher mass provides enhanced stability, ensuring that the cutting tool maintains its correct trajectory even during challenging or aggressive cutting operations.

To enhance machining accuracy, machine tool columns often integrate vibration isolation technologies to prevent external disturbances from affecting the machine's operation. Shock absorption systems or damping mounts can isolate the machine from external vibrations such as those generated by nearby equipment or external sources like traffic. These systems absorb and isolate any vibrations or shocks that may arise from external sources, ensuring that they do not compromise the precision of the machining process. The isolation of internal vibrations caused by the cutting process itself can prevent them from traveling to other parts of the machine, where they could impact the accuracy of subsequent machining operations. By limiting the transmission of both internal and external vibrations, the column ensures optimal cutting performance and consistent product quality.