Key Features of High-Quality Compressor Rotor Seats

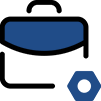

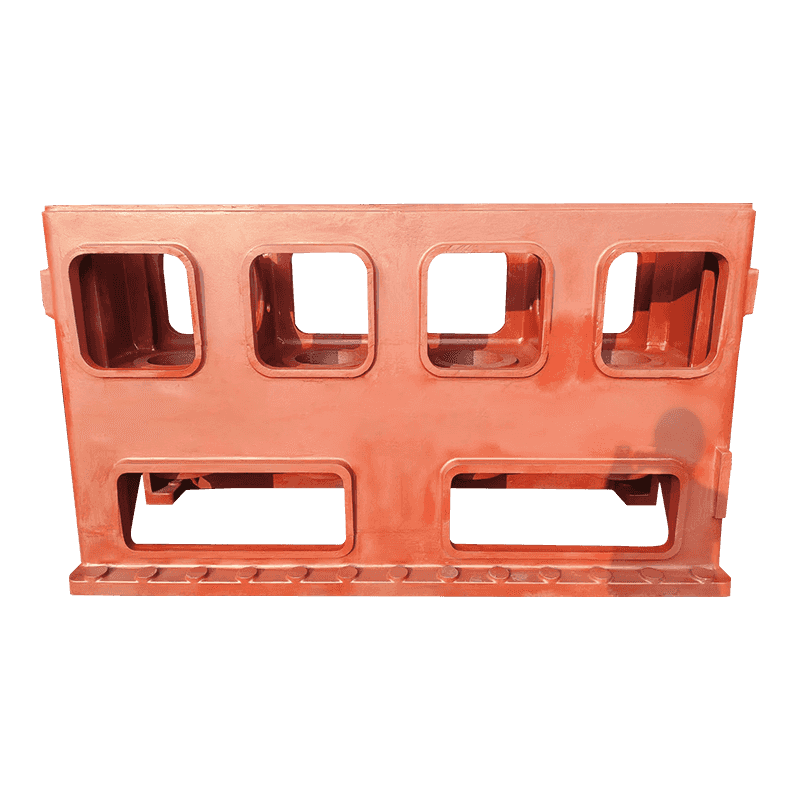

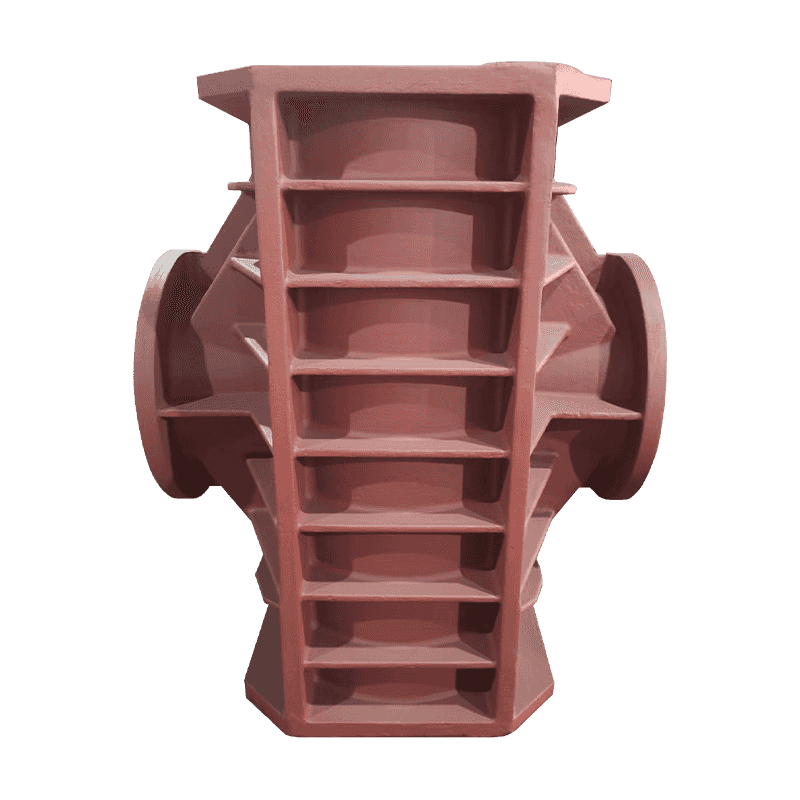

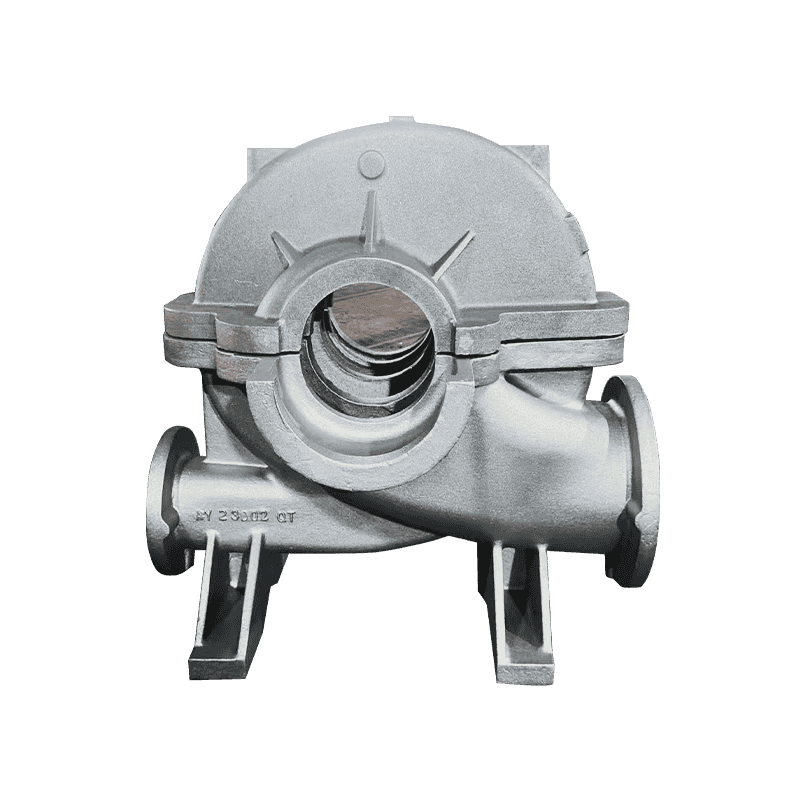

Compressor rotor seats are integral components within a compression system, serving as the foundation upon which the rotor operates. The quality of these components directly affects the efficiency, longevity, and overall performance of the compressor. Haian Aoyu Machinery Manufacturing Co., Ltd., a prominent China Compressor Rotor Seat manufacturer, sets a benchmark in the industry by producing rotor seats that embody superior quality and precision.

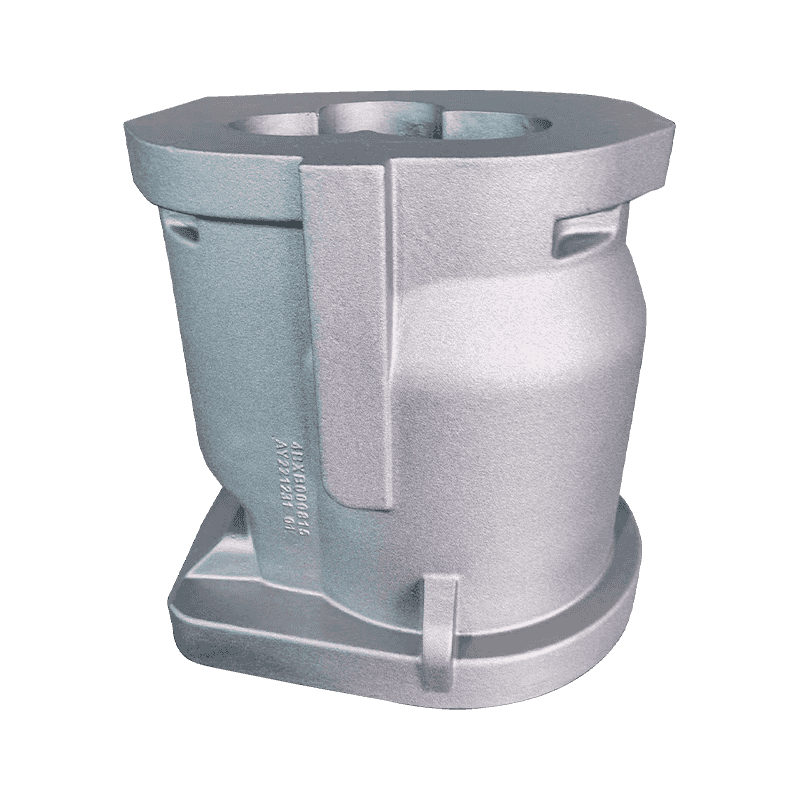

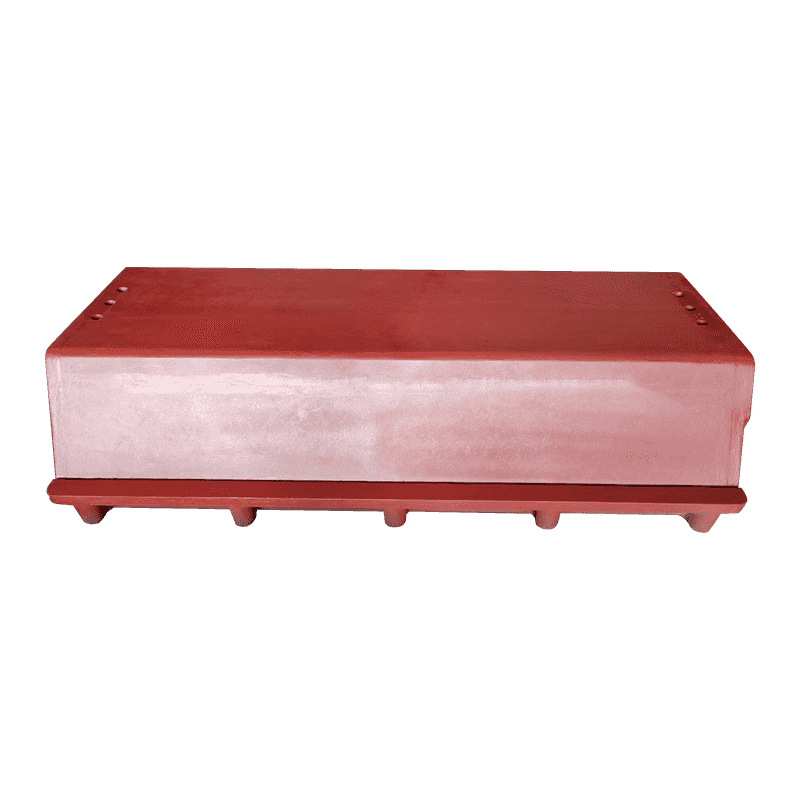

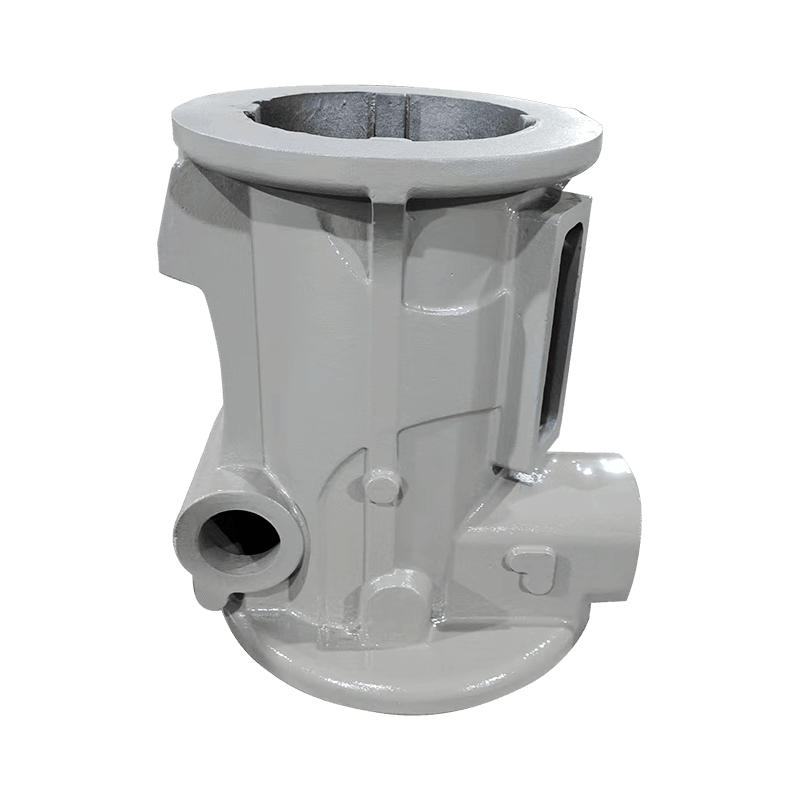

The material used in manufacturing compressor rotor seats is fundamental to their performance and durability. Haian Aoyu Machinery Manufacturing Co., Ltd. employs high-grade ductile iron and grey iron in their production processes. Ductile iron, known for its excellent tensile strength and ductility, ensures that the rotor seats can withstand significant mechanical stresses and operational demands. Grey iron, with its superior castability and vibration damping properties, contributes to the stability and smooth operation of the compressor. The choice of these materials reflects the company’s commitment to producing rotor seats that offer robustness and reliability.

Precision machining is crucial for achieving the exact dimensions and tolerances required for optimal performance. Haian Aoyu Machinery Manufacturing Co., Ltd. utilizes advanced machining technologies and equipment to ensure that each compressor rotor seat meets stringent specifications. The precision in machining reduces the risk of misalignment and operational issues, enhancing the efficiency and longevity of the compressor. The company’s dedication to maintaining tight tolerances and high machining standards underscores their expertise in producing high-quality rotor seats.

The structural integrity of a compressor rotor seat is vital for maintaining its performance under various operational conditions. Haian Aoyu Machinery Manufacturing Co., Ltd. places a strong emphasis on ensuring that their rotor seats possess exceptional structural strength. The manufacturing process involves rigorous testing and quality control measures to verify the strength and durability of each component. By focusing on structural integrity, the company ensures that their rotor seats can endure the mechanical forces and vibrations encountered during operation, reducing the likelihood of premature failure.

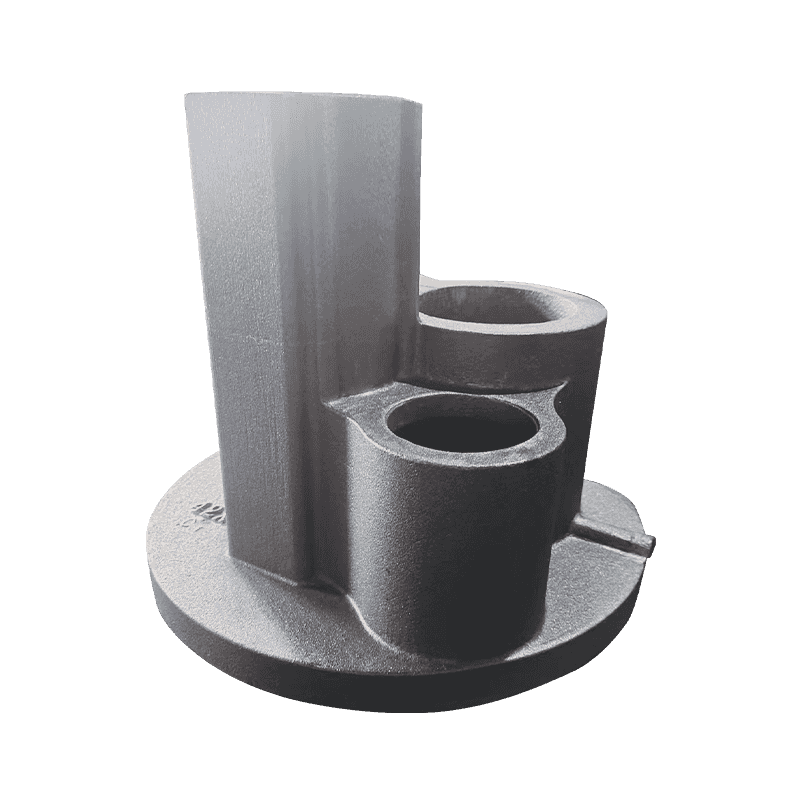

Compressors often operate in environments where temperature fluctuations and exposure to corrosive elements are common. High-quality rotor seats from Haian Aoyu Machinery Manufacturing Co., Ltd. are designed to withstand such conditions. The use of advanced materials and coatings enhances the thermal and corrosion resistance of the rotor seats. This feature is particularly important for applications in harsh environments or where the compressor is exposed to extreme temperatures and corrosive substances. The company’s focus on these aspects ensures that their rotor seats maintain performance and reliability over time.

The design and engineering of compressor rotor seats play a significant role in their functionality. Haian Aoyu Machinery Manufacturing Co., Ltd. employs a team of skilled engineers and designers who focus on creating rotor seats that meet the highest standards of performance and efficiency. The company’s design process incorporates advanced modeling and simulation techniques to optimize the geometry and functionality of the rotor seats. This engineering excellence ensures that the rotor seats not only fit perfectly within the compressor system but also contribute to its overall efficiency and performance.

Quality assurance is a critical component of the manufacturing process for high-quality compressor rotor seats. Haian Aoyu Machinery Manufacturing Co., Ltd. implements a comprehensive quality control system to ensure that every rotor seat meets rigorous standards. The company conducts various tests, including dimensional checks, material property assessments, and performance evaluations, to verify the quality and reliability of their products. These quality assurance practices help identify and address potential issues before the rotor seats reach the market, ensuring that customers receive only the highest quality components.

Different applications may require specific features or modifications in compressor rotor seats. Haian Aoyu Machinery Manufacturing Co., Ltd. offers customization options to meet the unique needs of their clients. The company’s ability to tailor their products based on customer specifications demonstrates their flexibility and commitment to providing solutions that address specific operational requirements. Whether it’s adjusting the design, materials, or dimensions, Haian Aoyu works closely with clients to deliver rotor seats that align with their particular needs.