- Technical Parameters

- Ecterprise Strength

- Any Question

|

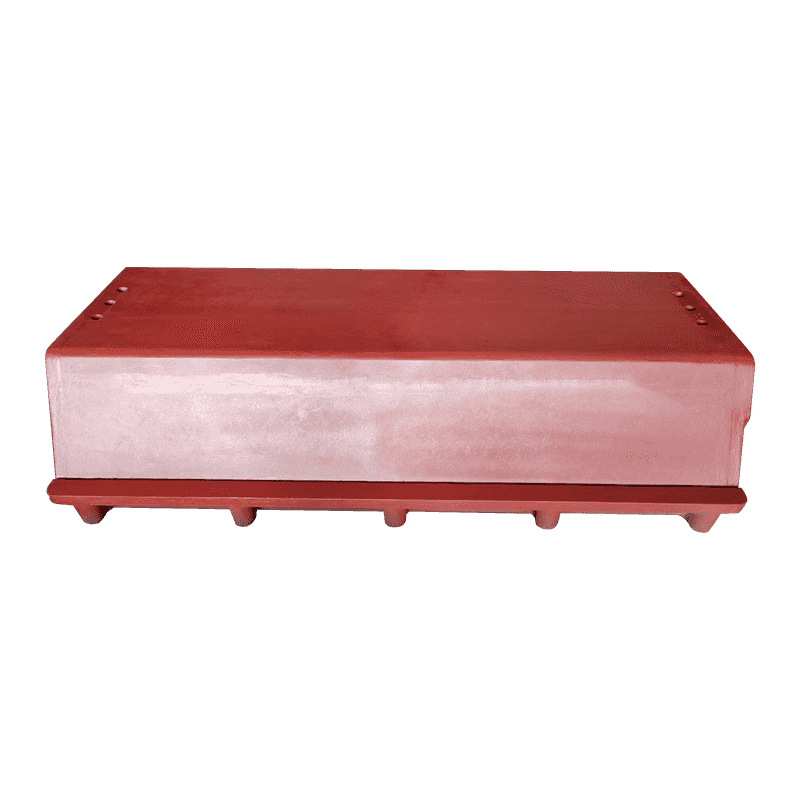

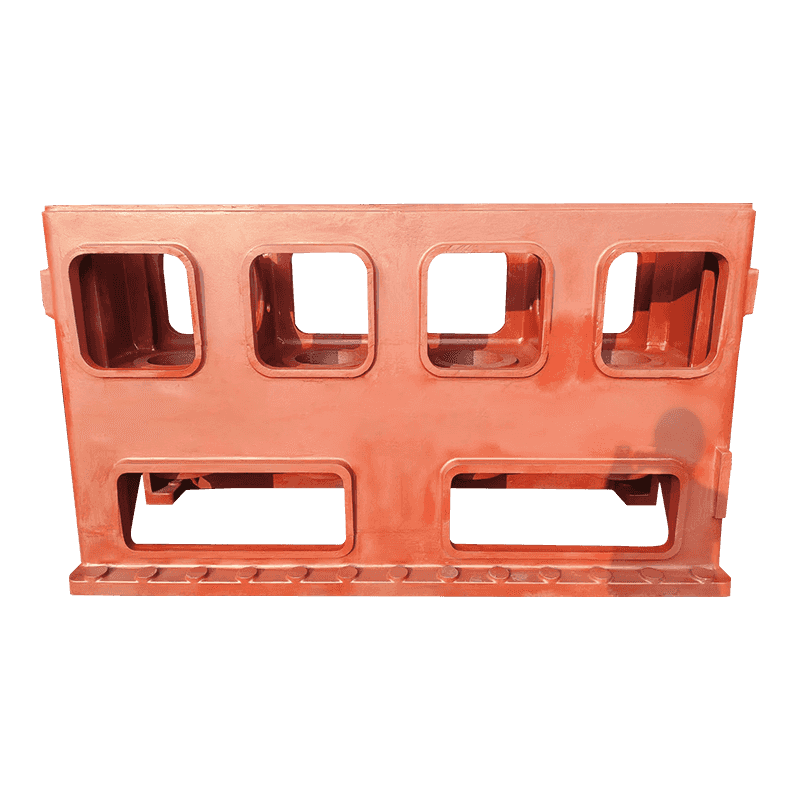

Product name |

compressor crankcase |

|

Brand |

HT250 |

|

Craftsmanship |

Inherited resin sand |

|

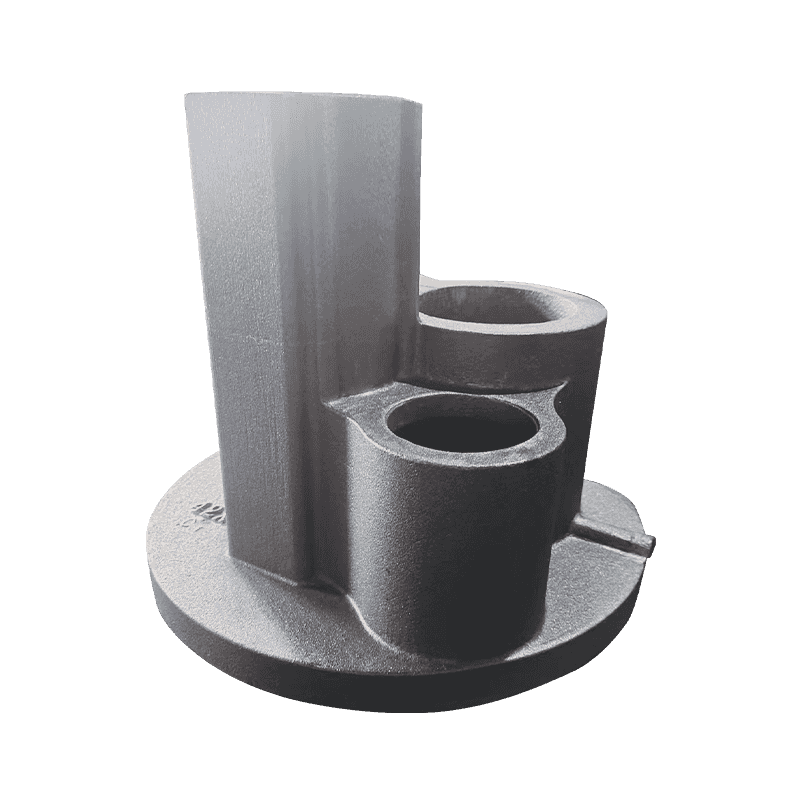

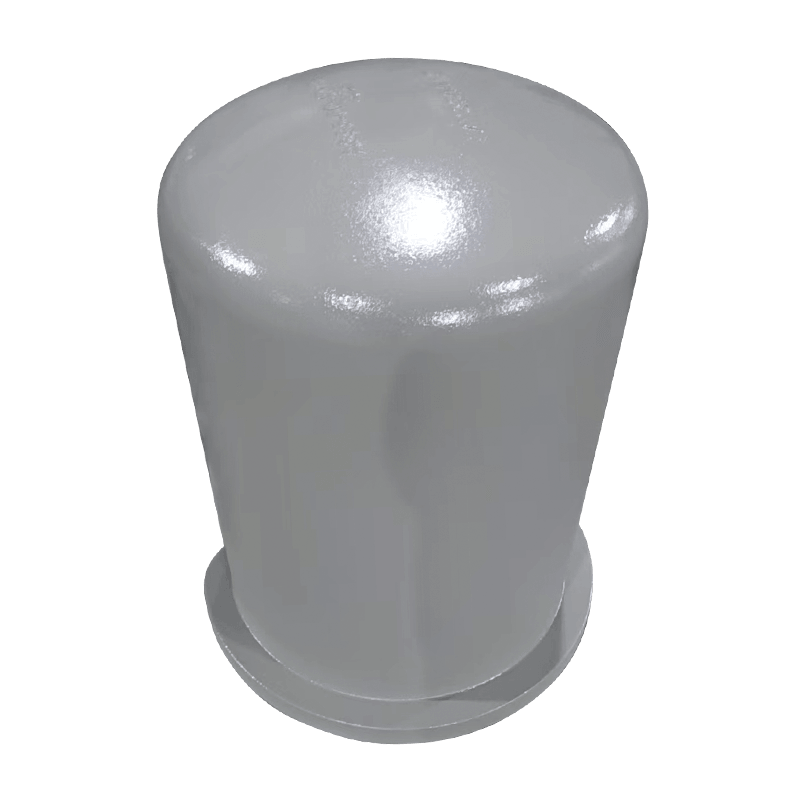

Category |

Compressor Castings |

About Haian Aoyu Machinery Manufacturing Co., Ltd.

Haian Aoyu Machinery Manufacturing Co., Ltd. was established in 2007. The company covers an area of 6000m² and has more than 200 employees. It is an industry-trade enterprise specializing in the production of water pumps. It can produce more than 30,000 pumps of various types, mainly exported to Europe, Asia, Africa, America, and other regions.

The company has rich experience in the design and manufacture of submersible pumps and sewage pumps, advanced automated production lines, testing equipment, and production processes, a group of professional technical engineers, and a strong R&D team. Since the establishment of the company, the products have been produced in strict accordance with international standards. Every position in production, sales, and after-sales has a superb technical team to back it up. Every link is under strict quality control to ensure that all sales are high-quality products. The employees of the company always keep in mind that quality is the life of an enterprise, and they are professional because of concentration, and we have been working hard.

-

Products Integration

-

15+ Industrial Experience

-

Export To Over 35 Countries

-

7*24 Hours Customer Service

-

High Tensile Strength and Ductility Ductile Iron Parts are distinguished by their spheroid...

READ MORE -

Understanding Internal Stresses in Machine Tool CastingsDuring the casting process, Machin...

READ MORE -

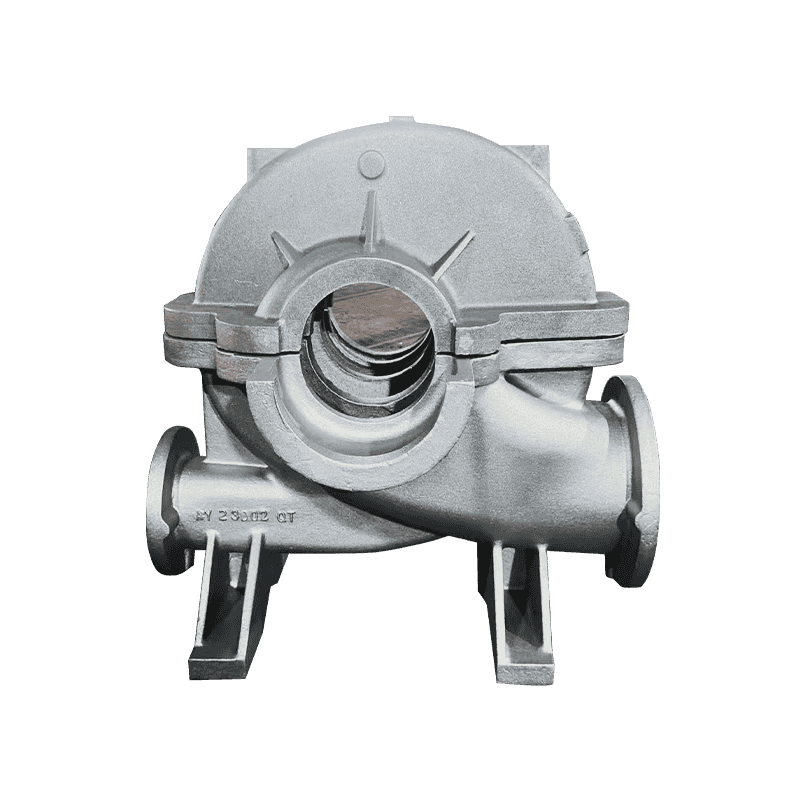

Structural Rigidity and Vibration ControlCompressor Castings form the primary structural...

READ MORE -

Precision Machining and Tight Tolerances The foundation of effective high-speed operation ...

READ MORE -

Precision Machining and Tolerance ControlA Piston Pump Valve Body achieves reliable sealin...

READ MORE

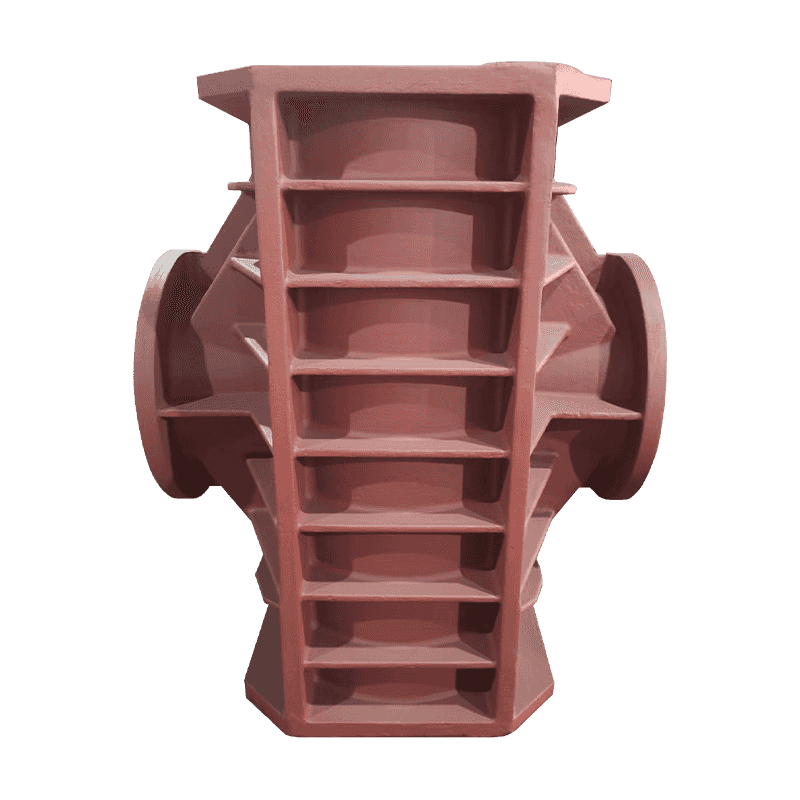

1. How Does Our Compressor Crankcase Achieve Superior Vibration Damping and Absorption?

At Haian Aoyu Machinery Manufacturing Co., Ltd., we understand that effective vibration control is essential for the optimal performance of compressors. Our compressor crankcases are meticulously engineered to excel in vibration damping and absorption. The primary material used in our crankcases is high-grade ductile iron, chosen for its excellent capacity to absorb and dampen vibrations. Ductile iron offers superior shock resistance compared to conventional cast iron, providing a solid foundation for managing mechanical stresses and vibrations that occur during compressor operation.

The design of our crankcases incorporates advanced techniques such as internal ribbing and optimized geometry, which enhance the overall stiffness and rigidity of the component. This design approach helps to distribute vibrational forces evenly, reducing the impact on the compressor and associated machinery. By minimizing vibration, our crankcases not only contribute to smoother operation but also help in extending the lifespan of the entire compressor system. This is particularly important in industrial applications where prolonged exposure to vibrations can lead to premature wear and failure of components.

Our state-of-the-art manufacturing processes include precision machining and rigorous quality control measures. These processes ensure that each crankcase meets stringent specifications for vibration damping. We conduct comprehensive testing to simulate real-world conditions and verify that our crankcases consistently perform at the highest standards. This commitment to quality guarantees that our products deliver exceptional performance and reliability, providing peace of mind to our clients across various industries.

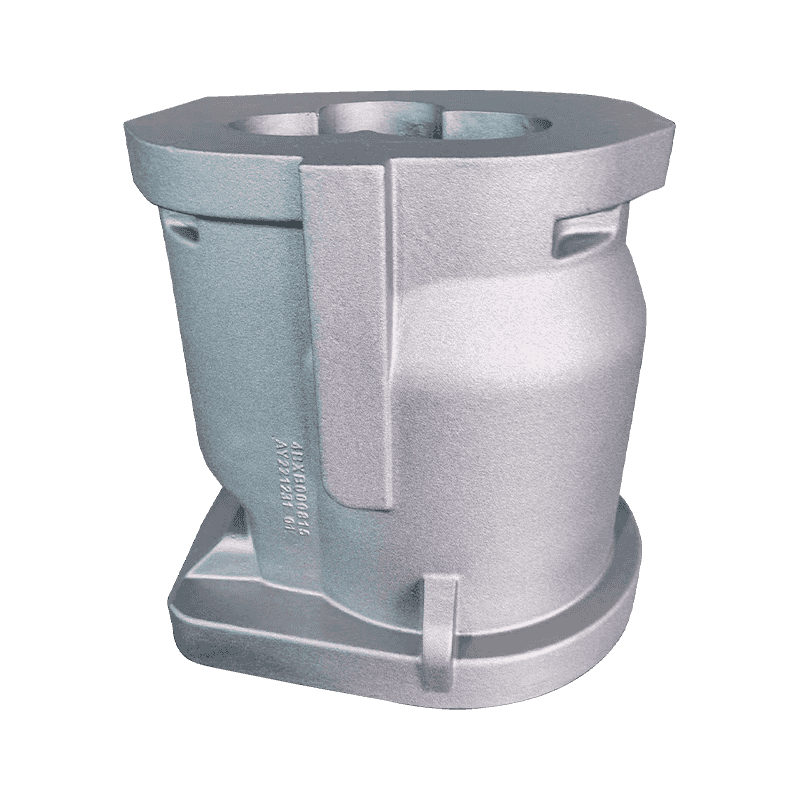

2. What Are the Key Advantages of Our Crankcases in Terms of Wear Resistance and Lubrication?

Wear resistance and lubrication are critical factors in the performance and longevity of compressor crankcases. At Haian Aoyu Machinery, we prioritize these aspects by using high-quality materials and advanced manufacturing techniques. Our crankcases are crafted from premium ductile iron and grey iron, both known for their outstanding wear-resistant properties. This choice of material ensures that our crankcases can withstand the intense mechanical stresses and abrasive conditions typically encountered in compressor systems.

Ductile iron, in particular, offers superior wear resistance due to its high tensile strength and impact resistance. This material minimizes the likelihood of surface degradation and mechanical failures, which can be caused by friction and wear. Additionally, the inherent lubrication properties of our crankcases are enhanced by the precise design and machining processes. We implement advanced techniques to ensure optimal lubrication channels within the crankcase, facilitating effective distribution of lubricants and reducing friction between moving parts.

Our crankcases undergo rigorous testing to assess their performance in real-world conditions. We simulate various operational scenarios to evaluate wear resistance and lubrication efficiency, ensuring that our products maintain peak performance over extended periods. This thorough testing process helps to identify potential issues early and allows us to make necessary adjustments to improve product durability and reliability.

The result is a crankcase that not only performs exceptionally well but also contributes to reduced maintenance costs and extended service intervals. Our commitment to using high-quality materials and employing advanced manufacturing techniques ensures that our crankcases meet the highest standards of wear resistance and lubrication, providing long-lasting value for our customers.

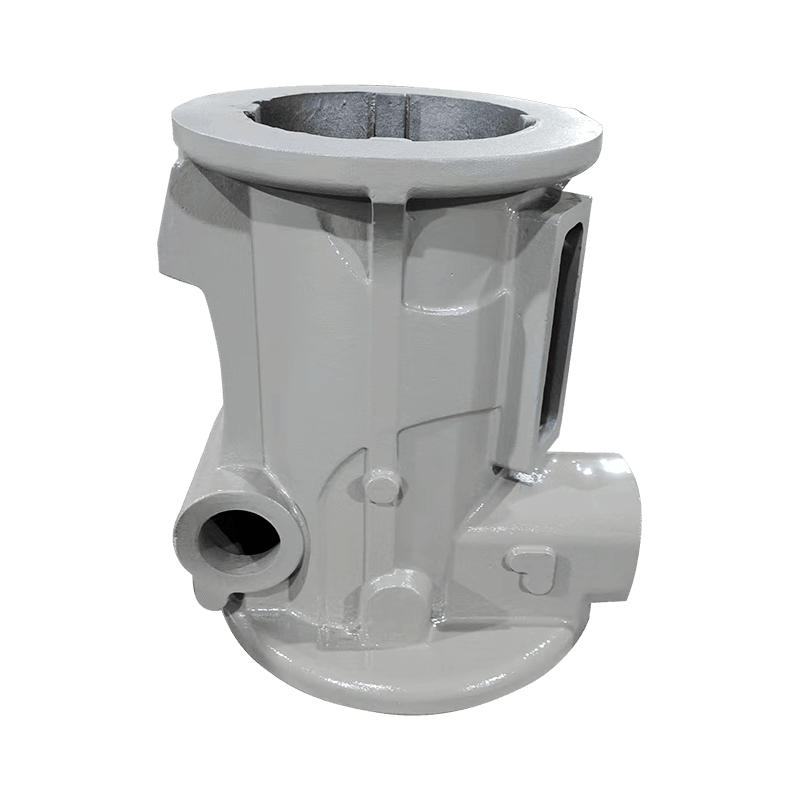

3. How Does Our Crankcase Design Enhance Molding Performance and Surface Hardness?

The design and molding performance of our compressor crankcases are critical factors in ensuring the overall quality and longevity of the product. At Haian Aoyu Machinery, we utilize advanced molding techniques and high-quality materials to achieve superior results. Our crankcases are produced using precision molding processes that guarantee consistent dimensions and optimal performance.

One of the key aspects of our design is the focus on dense and anti-leakage performance. Our molding techniques ensure that the crankcases are free from defects such as air pockets and inclusions, which can compromise structural integrity and lead to leakage issues. We employ sophisticated technologies and rigorous quality control measures to achieve a high level of density and prevent leakage, ensuring that our crankcases perform reliably under various operating conditions.

The surface of the bed guide rail in our crankcases is specially treated through a quenching process to achieve high hardness. This treatment enhances the wear resistance and durability of the crankcase, contributing to its extended service life. The quenching process involves heating the crankcase to a specific temperature and then rapidly cooling it, which results in a hard, wear-resistant surface layer. This increased hardness is crucial for maintaining the precision and stability of the crankcase under the mechanical stresses encountered during compressor operation.

Our commitment to excellent molding performance and surface hardness is reflected in the quality and reliability of our products. We continuously invest in research and development to refine our manufacturing processes and incorporate the latest advancements in material science and engineering. This dedication ensures that our crankcases not only meet but exceed industry standards, providing exceptional performance and value for our clients.