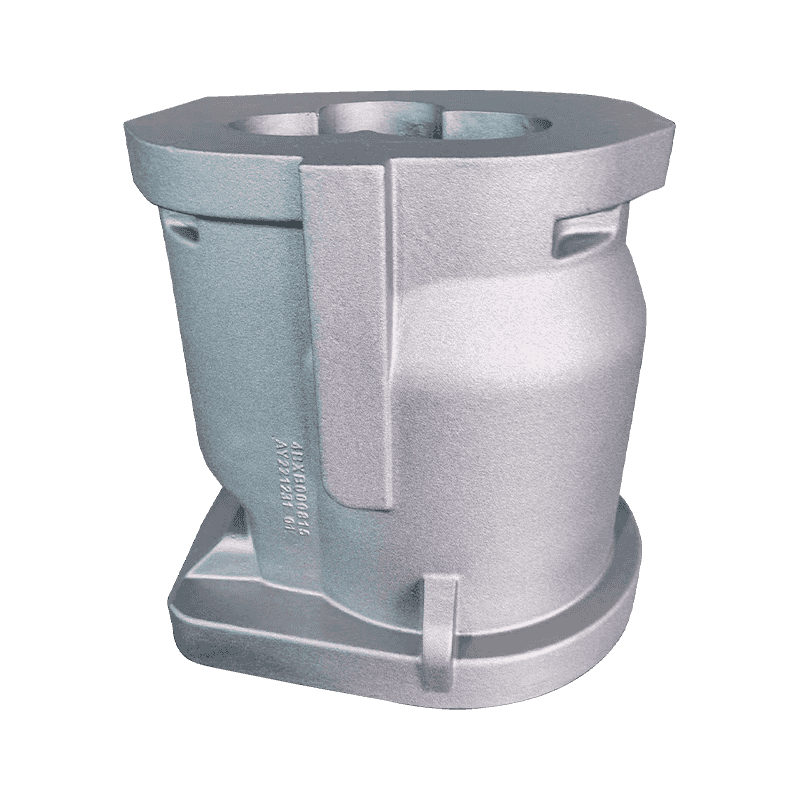

The selection of materials for pump and valve castings is paramount in managing thermal expansion. Materials such as cast iron, stainless steel, and aluminum have distinct coefficients of thermal expansion (CTE) that determine how they respond to temperature variations. For instance, stainless steel has a lower CTE compared to aluminum, making it more stable under temperature fluctuations. Engineers carefully assess the operational temperature range and environmental conditions when selecting materials, ensuring they can withstand the thermal stresses encountered during operation without significant deformation or failure.

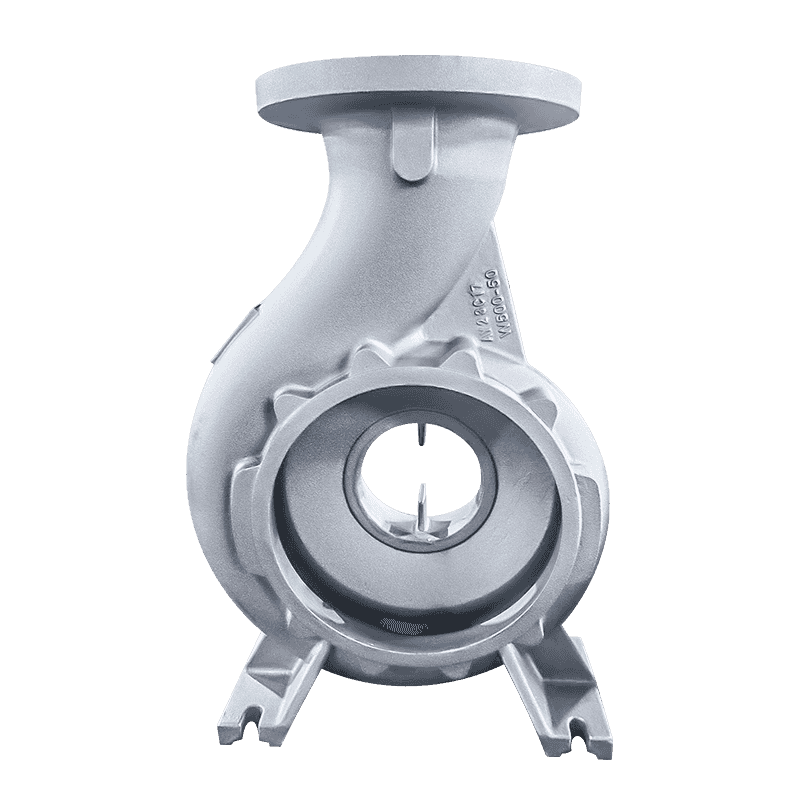

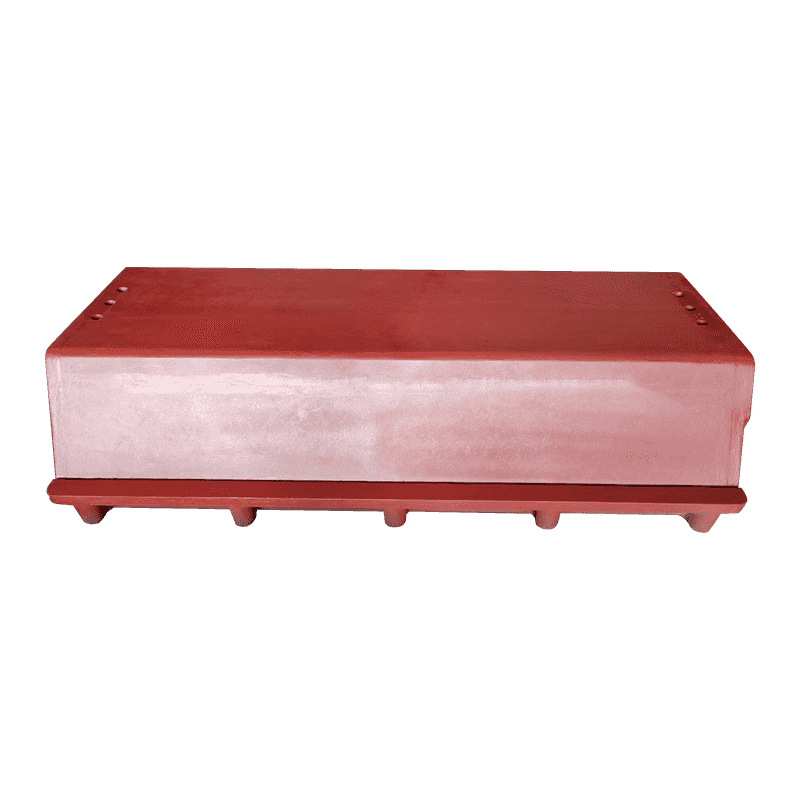

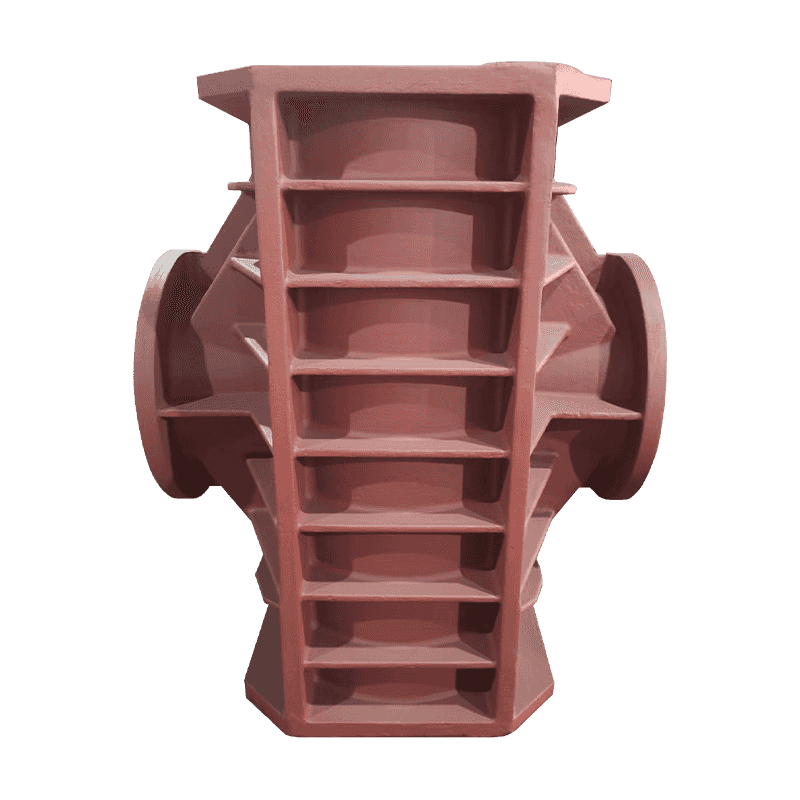

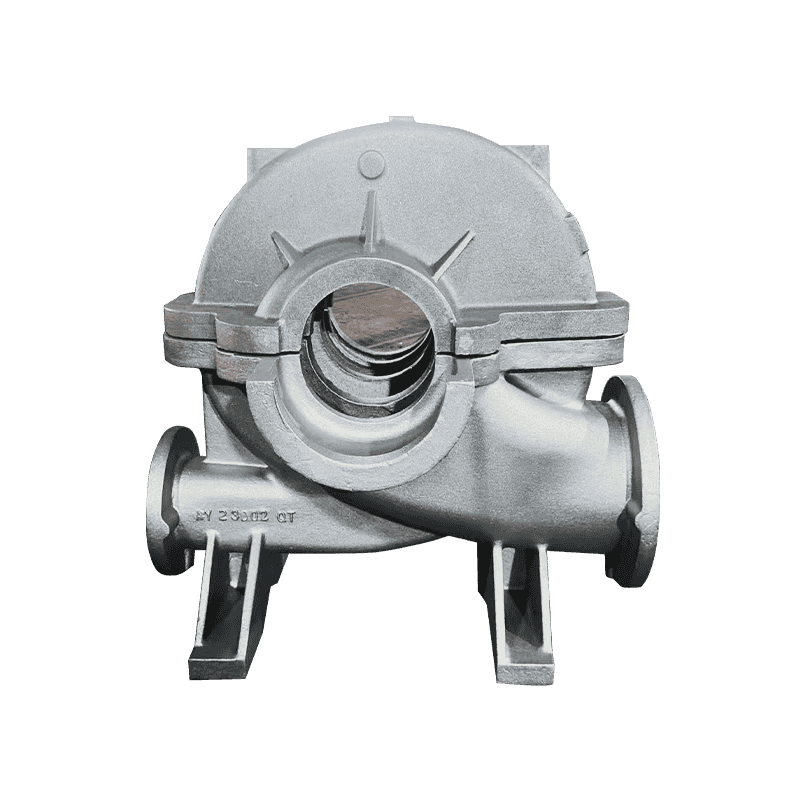

Effective design is essential for accommodating thermal expansion and contraction. Engineers incorporate tolerances and clearances into the design to allow for thermal movement without inducing undue stress. This may involve designing components with sliding fits or flexible joints that can absorb expansion without creating binding or interference. The design may also include features like ribbing or gussets, which can enhance structural integrity while providing room for expansion.

The design of joints and connections is critical for maintaining system integrity under thermal cycling. Bolted connections, for example, can be engineered to maintain a certain degree of flexibility, which is vital for preventing leaks and structural failure due to thermal expansion. Using flange designs that allow for some movement can help accommodate the expansion without compromising the sealing performance. The use of gaskets and seals specifically rated for thermal expansion can also enhance the reliability of these connections.

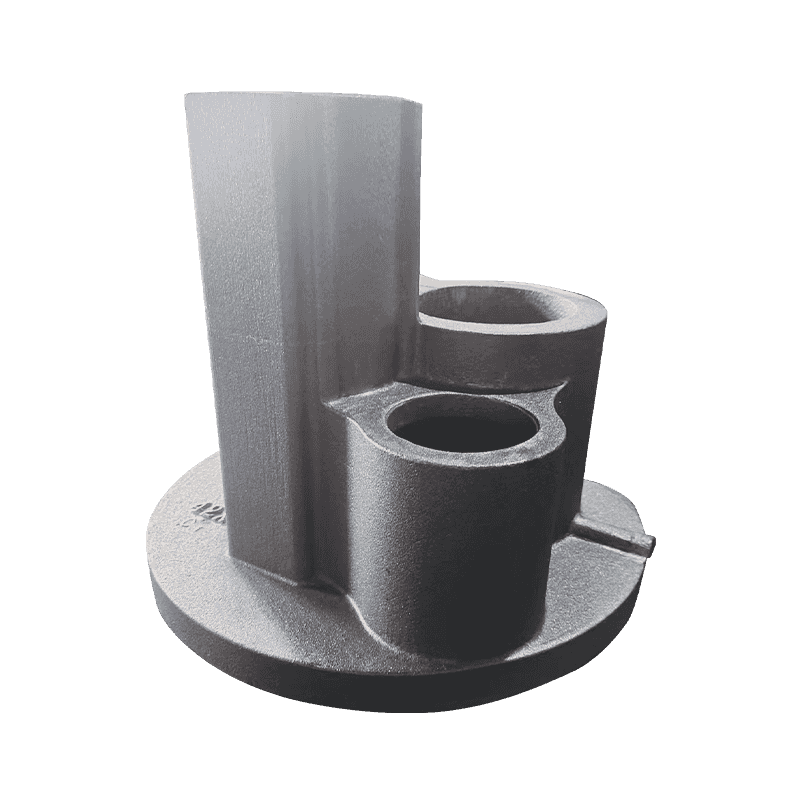

Heat treatment processes are often employed to enhance the mechanical properties of castings. Techniques such as annealing or stress relief are used to reduce residual stresses that can develop during the casting process. By normalizing the material structure, these treatments improve the material’s ability to withstand thermal cycling and minimize the risk of cracking or warping. The choice of heat treatment process depends on the specific material and intended application, requiring careful consideration by engineers.

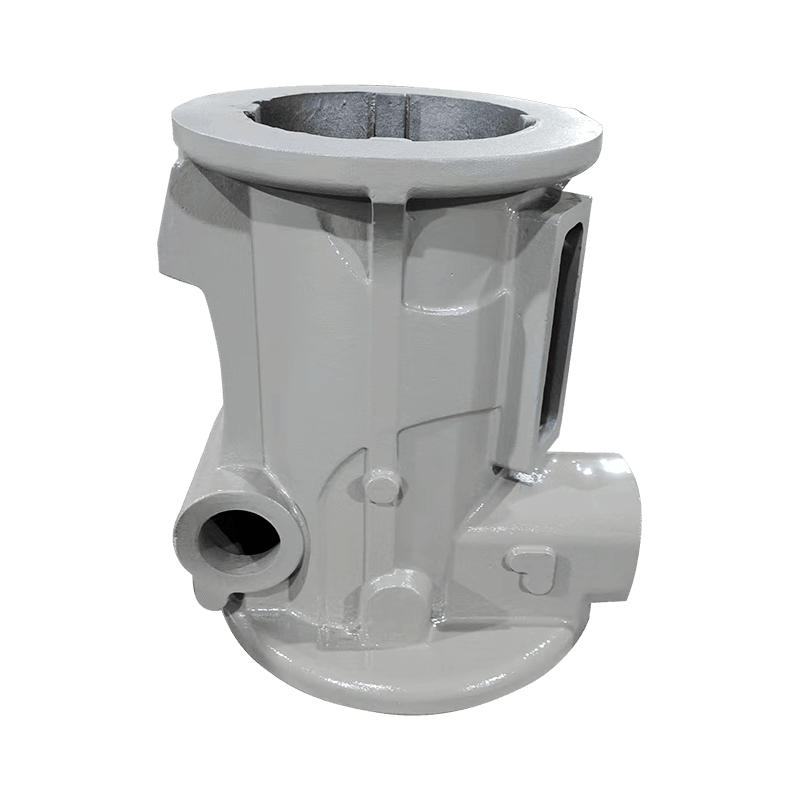

The thermal characteristics of the fluids being transported through pumps and valves significantly influence the thermal behavior of the cast components. For example, fluids with high flow rates can generate heat due to friction, affecting the temperature of the surrounding castings. Engineers must consider the thermal conductivity of both the fluid and the casting materials to predict how heat will transfer within the system. Understanding these dynamics is critical for ensuring that components remain within acceptable temperature ranges during operation.

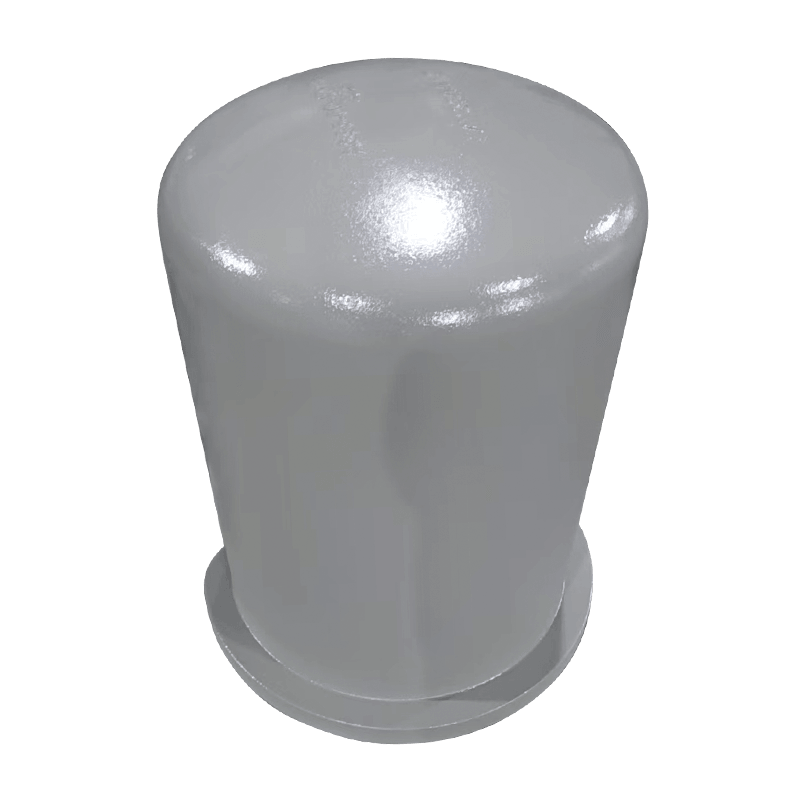

In applications where temperature control is vital, external thermal insulation may be applied to pumps and valves. Insulation helps to mitigate temperature fluctuations by maintaining a consistent operating temperature, thus reducing the magnitude of thermal expansion and contraction cycles. This practice is particularly relevant in processes involving high-temperature fluids or environments where temperature stability is critical for operational efficiency and safety.

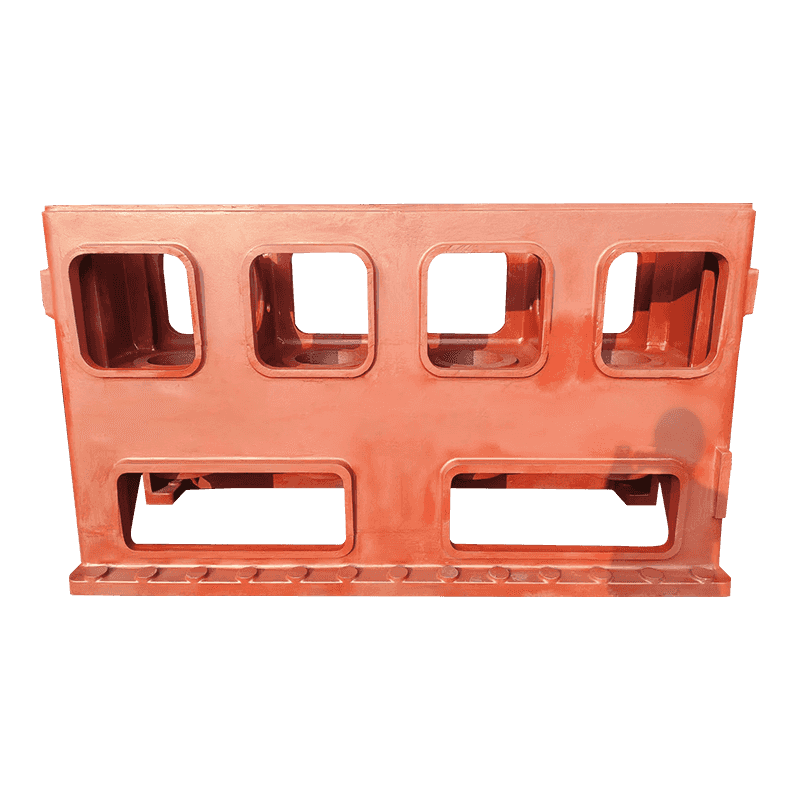

For larger systems, particularly those with significant thermal movement, expansion joints may be incorporated to absorb and accommodate movement due to thermal expansion. These joints allow for controlled flexibility within the piping system, helping to reduce stress on cast components and maintaining overall system integrity. Engineers must carefully select the type and placement of expansion joints based on expected thermal expansion rates and the specific design of the system.