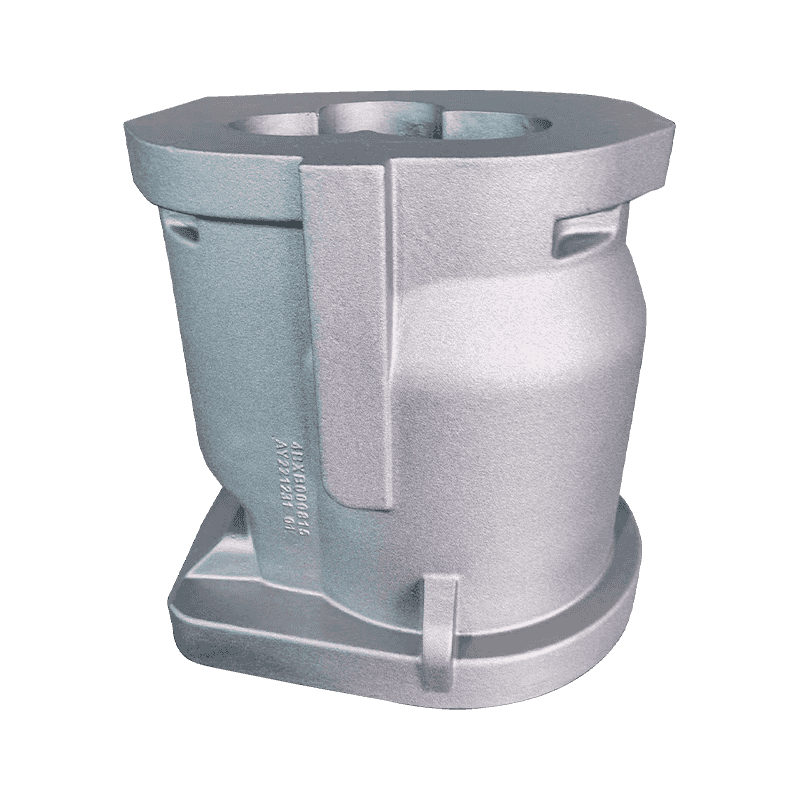

Thermal Expansion and Contraction: Temperature variations cause materials to expand and contract, a fundamental principle that directly affects the integrity of compressor coated sand cylinders. As temperatures rise, the metallic and non-metallic components of the cylinder, including the coating, may experience expansion. Over time, repeated thermal expansion can lead to misalignments between moving parts, creating undue friction and mechanical stresses. These stresses can compromise the bond between the coating and the cylinder’s inner surfaces, leading to potential cracking or flaking of the protective layer. Conversely, low temperatures cause contraction, which may lead to gaps or looseness in the structural components. This can reduce the efficiency of the system by allowing unwanted play between parts, increasing wear and reducing operational precision.

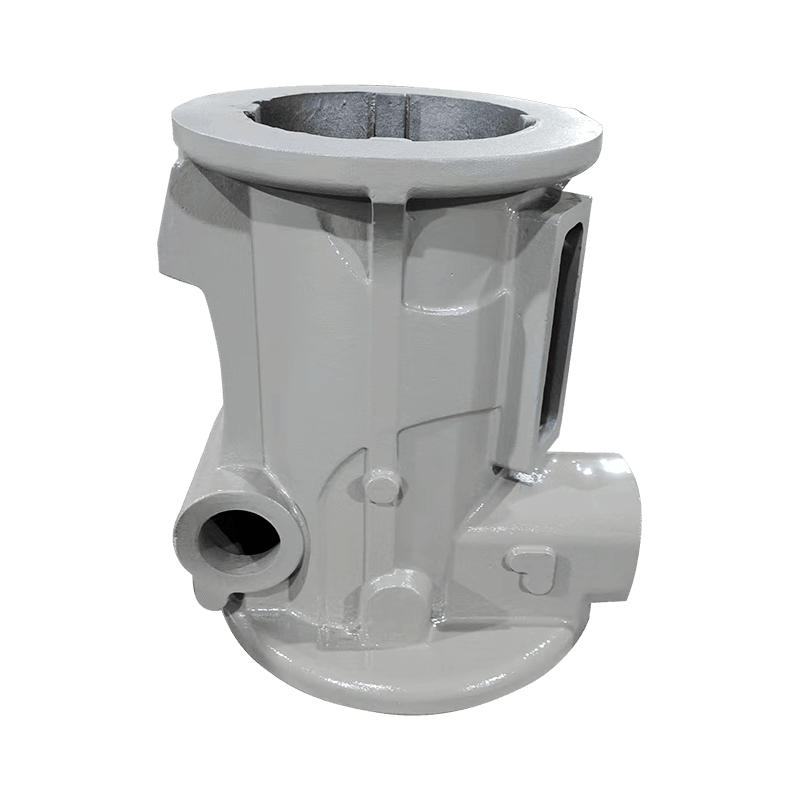

Changes in Material Properties: The physical properties of both the coating and the sand inside the cylinder are sensitive to temperature changes. High temperatures can cause the protective coating to soften, reducing its ability to effectively shield the cylinder from abrasive wear, corrosion, and impact damage. If the coating material exceeds its thermal tolerance, it may degrade or break down entirely, leaving the internal structure exposed to wear and environmental conditions. On the other hand, extremely low temperatures may cause the coating to become brittle, making it more prone to cracking or chipping. In both cases, the compromised coating would fail to protect the internal components, potentially leading to premature cylinder failure or diminished performance.

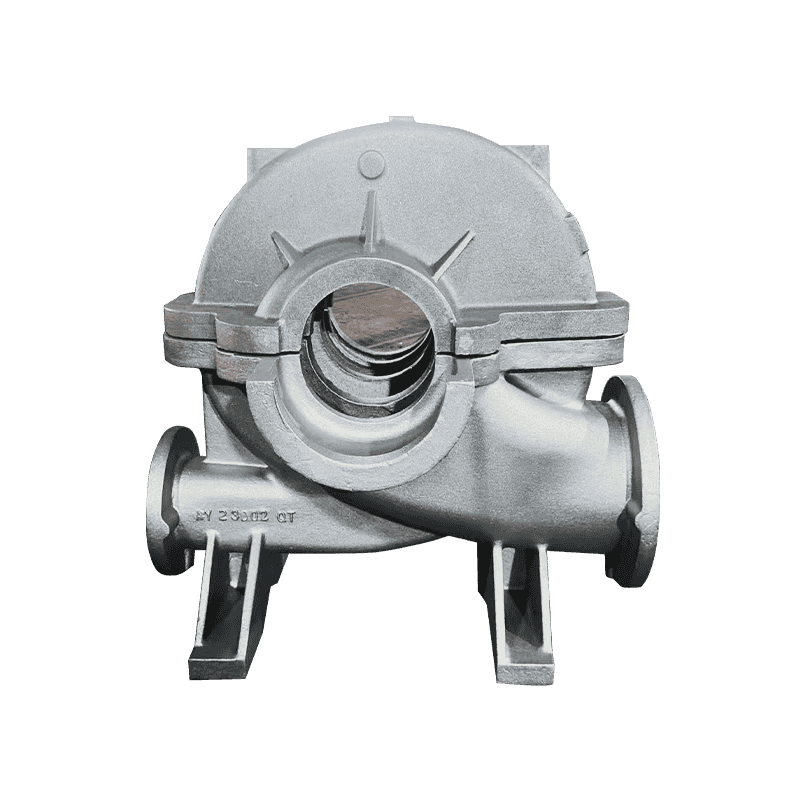

Viscosity of Lubricants: Lubrication plays a critical role in reducing friction, minimizing wear, and ensuring the smooth operation of a compressor coated sand cylinder. However, temperature fluctuations can significantly impact the viscosity of lubricants. At elevated temperatures, lubricants may become too thin, losing their ability to adequately coat surfaces and protect against friction and heat buildup. This increased metal-on-metal contact can result in accelerated wear and reduced efficiency. Conversely, in colder environments, lubricants can thicken, becoming more viscous and less effective at penetrating moving parts. This increase in resistance can cause the system to overwork, leading to higher energy consumption and a reduction in overall performance.

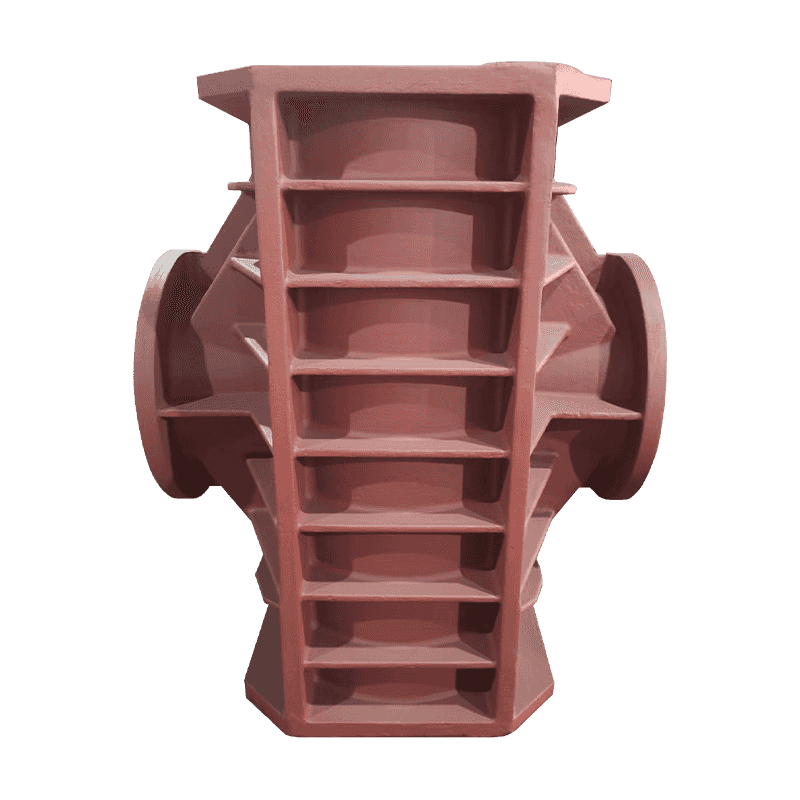

Compressive Strength of Coated Sand: The coated sand within the cylinder is designed to withstand significant compressive forces during operation. However, exposure to high temperatures can reduce the compressive strength of the sand, diminishing its ability to absorb mechanical loads. This reduction in strength can lead to structural deformation or even failure of the coated sand layer, especially under high pressure or repeated load cycles. Prolonged exposure to elevated temperatures can cause the sand particles and their coating to lose integrity, reducing their capacity to buffer and protect the cylinder from internal pressures and mechanical stress. This could result in diminished efficiency, increased wear on critical components, and a higher likelihood of system breakdown.

Seal and Gasket Performance: Seals and gaskets are crucial for maintaining pressure and preventing leaks in compressor systems. However, they are particularly sensitive to temperature fluctuations. In cold conditions, seals and gaskets may harden and shrink, reducing their ability to form a tight seal. This shrinkage can result in air or fluid leakage, reducing the efficiency of the cylinder and increasing the risk of contamination or system failure. In hot conditions, seals and gaskets may soften or degrade, leading to deformation or melting. This compromises their sealing capabilities, potentially causing leaks that could lead to a sudden drop in pressure or system shutdown. Ensuring that seals and gaskets are made from temperature-resistant materials is critical to maintaining system reliability in fluctuating environments.