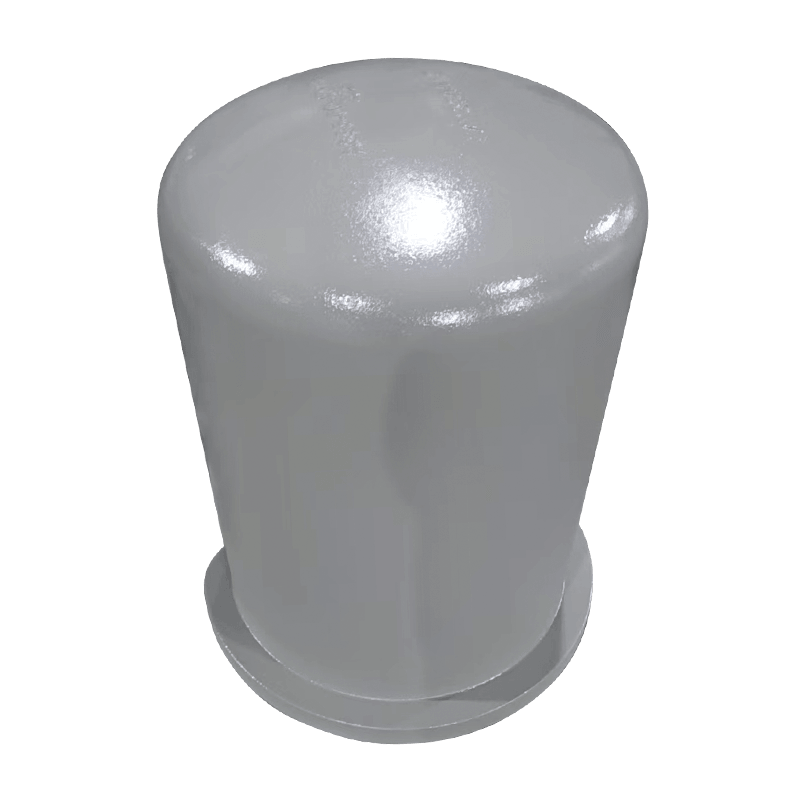

The compressor short oil barrel is specifically engineered to have a lower profile compared to traditional, taller oil barrels. This compact height not only makes the barrel more ergonomically accessible but also allows for better stackability in environments with limited storage space. The reduced height enables the barrel to be stored in a more organized and efficient manner, minimizing the amount of vertical space needed in warehouses, workshops, or maintenance areas. The compact size also makes it possible to store the barrels side-by-side on shelves or pallets, which maximizes horizontal storage capacity.

The shorter and wider design of the compressor short oil barrel makes it significantly easier to move and transport compared to the bulkier, taller standard oil barrels. The reduction in height and the more stable, wider base contribute to a more balanced profile, which reduces the likelihood of the barrel tipping over during handling. Its lighter weight, due to the smaller size and efficient material use, enhances manual mobility in small or congested spaces. This increased portability allows workers to move the barrel easily from storage to maintenance areas, and in field operations, where mobility is key, this design minimizes the need for heavy equipment like forklifts or mechanical lifting devices.

Storage is one of the most significant concerns in industrial environments, particularly when managing large quantities of lubricants or oils for compressors. The short oil barrel's compactness allows for a more efficient use of storage space. Compared to traditional oil barrels, which require a considerable amount of vertical clearance, the shorter barrel allows for denser storage with the potential to store more barrels in the same area. This efficiency is critical in settings with limited space, such as maintenance departments, small workshops, or mobile service trucks. The uniform design of the compressor short oil barrel helps to streamline the storage and retrieval process, as the barrel can be stored horizontally, stacked, or placed side by side, reducing wasted space between units.

The design of the compressor short oil barrel not only improves space efficiency but also optimizes the dispensing process. Due to its shorter height, workers can easily access the barrel to fill compressors or other machinery with minimal physical effort. Unlike traditional oil barrels, which often require lifting or tilting, the short oil barrel’s design enables users to dispense oil without needing to raise the barrel, thus reducing the risk of spills and increasing accuracy in oil application. Many compressor short oil barrels also come with integrated spouts, easy-drain mechanisms, or pump systems that ensure controlled, spill-free dispensing. The ease of access and user-friendly design of these barrels leads to faster and more precise operations, resulting in improved workflow and reduced downtime during maintenance procedures.

The wider diameter and lower center of gravity of a compressor short oil barrel contribute to greater stability during handling. Standard oil barrels, due to their taller structure, can be cumbersome and prone to tipping when being moved manually, especially if the oil barrel is not well-balanced or is overfilled. The short oil barrel, with its broader base, ensures a stable position while being lifted, transported, or rotated. This stability reduces the likelihood of oil spillage or barrel accidents, which can be hazardous in industrial settings. The design also allows for easier manual control in tight spaces, such as beneath machinery or within confined areas where movement is restricted.