What is the manufacturing process of Machine Base?

Haian Aoyu Machinery Manufacturing Co., Ltd. focuses on providing high-quality gray iron castings and ductile iron casting solutions. Our goal is to provide customers with a full range of services from casting process design to the final product. Machine Base is one of our products. The following will introduce the manufacturing process of Machine Base in detail, showing our strict control of quality and precision in every link.

1. Casting process design

The manufacturing process of the machine base begins with casting process design. At this stage, Haian Aoyu Machinery Manufacturing Co., Ltd.'s engineers will design the most suitable casting process according to customer needs and product usage conditions. We use furan resin sand process, which can provide excellent casting surface quality and dimensional accuracy. Through computer-aided design (CAD) and computer-aided engineering (CAE) software, we can simulate various situations in the casting process to optimize the design and prevent potential problems.

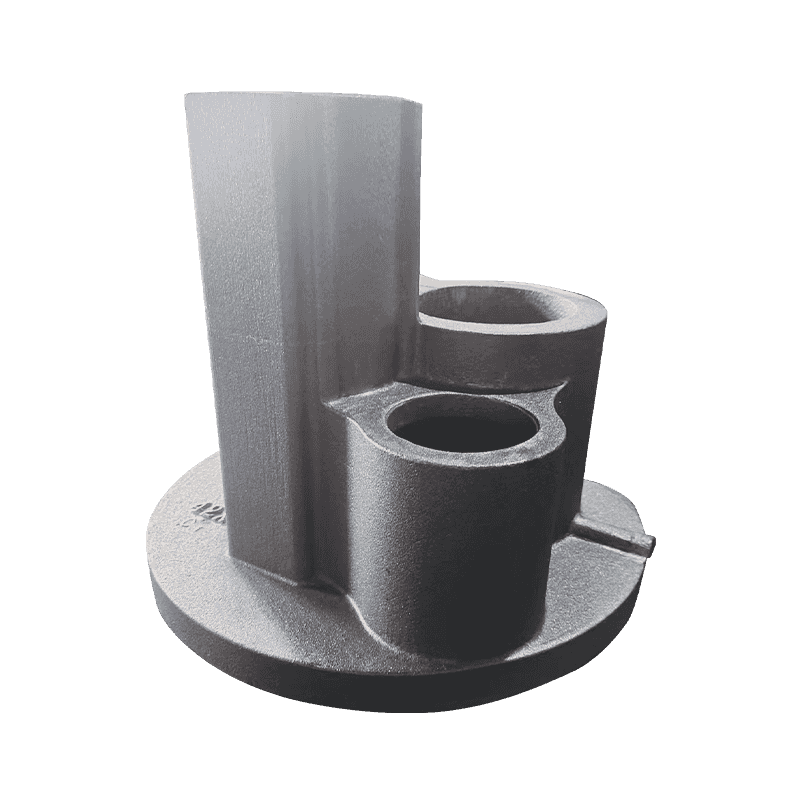

2. Mold production

After the casting process design is completed, Haian Aoyu Machinery Manufacturing Co., Ltd. enters the mold production stage. The mold is a key part of the casting process, which directly affects the shape and size of the final casting. We use high-precision processing equipment and technology to produce molds. Mold designers will make mold design plans based on casting process drawings. Next, we use CNC machine tools to process and trim the mold to ensure that every detail of the mold meets the design requirements. After the mold is made, it is also necessary to conduct strict inspections to ensure that it meets quality standards.

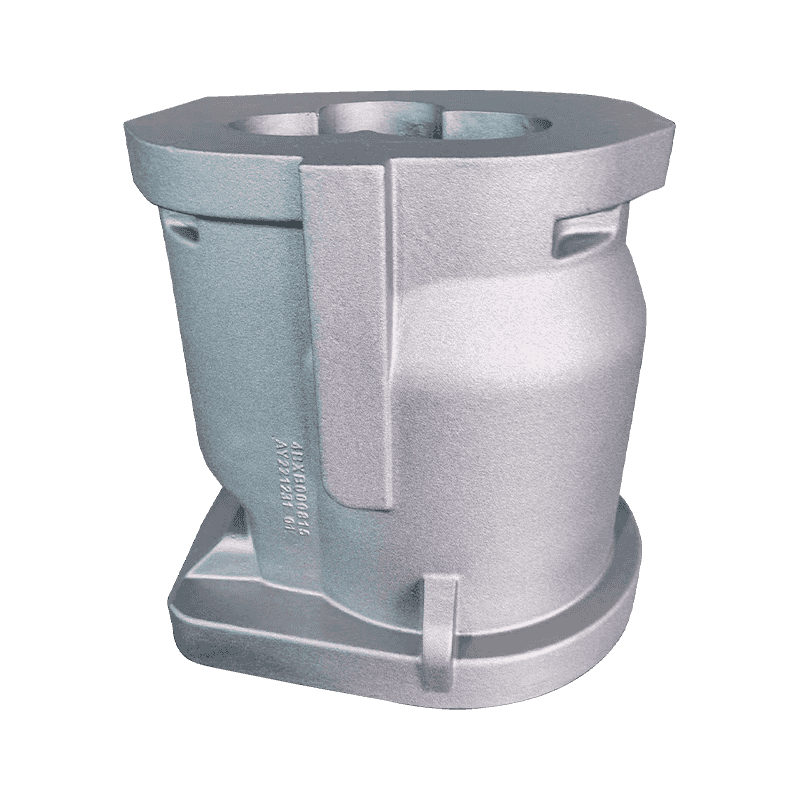

3. Casting production

After the mold is ready, casting production begins. The key steps in the casting process include sand mold making, smelting, pouring and cooling. Haian Aoyu Machinery Manufacturing Co., Ltd. uses furan resin sand as a casting material. This sand mold has excellent strength and heat resistance, which can ensure the dimensional stability of the casting. The smelting process in the casting process is also very important. We use advanced arc furnaces and induction furnaces for metal smelting to ensure the purity and uniformity of the molten metal.

The pouring process is a crucial step in casting. Haian Aoyu Machinery Manufacturing Co., Ltd. uses a fully automatic pouring system to ensure that the molten metal flows evenly into the mold and reduces the generation of gas and inclusions. After the casting cools in the mold, we will perform the first cleaning to remove the sand mold and excess metal parts. At this time, our quality inspection team will conduct a preliminary inspection of the casting to ensure that its surface quality and dimensions meet the standards.

4. Heat treatment

In order to improve the mechanical properties and durability of the castings, Haian Aoyu Machinery Manufacturing Co., Ltd. will heat treat the castings. The heat treatment process includes annealing, normalizing, quenching and other processes. Annealing can remove stress inside the casting and improve its toughness; normalizing can increase the hardness and strength of the casting; quenching is used to improve the wear resistance and hardness of the casting. We will select the appropriate heat treatment process according to the material and use requirements of the casting to ensure that the casting achieves the best performance.

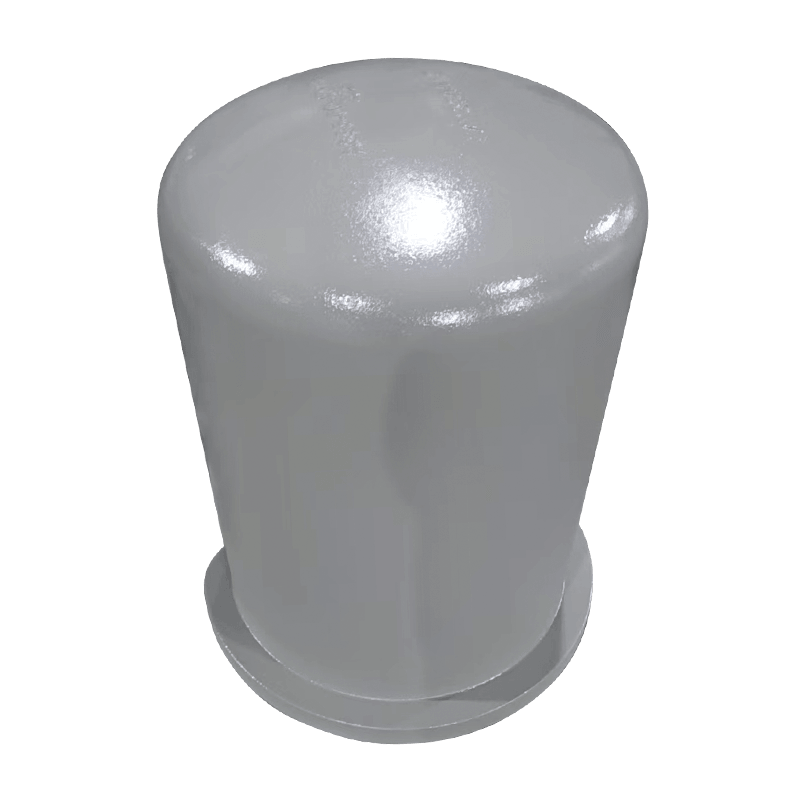

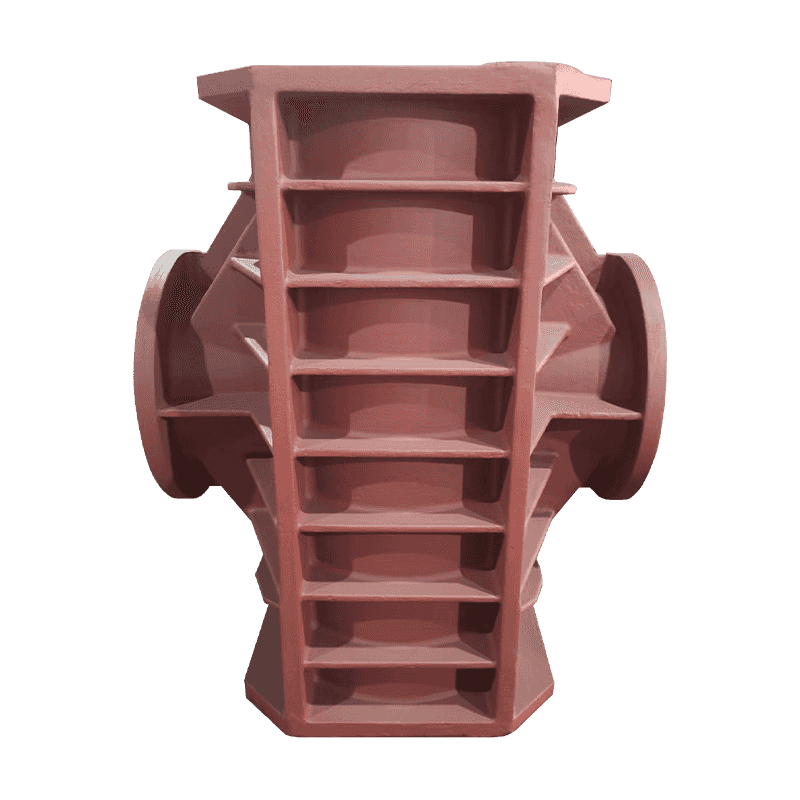

5. Coating

After the castings are heat treated, Haian Aoyu Machinery Manufacturing Co., Ltd. will coat them. The coating can prevent corrosion on the surface of the casting and improve its appearance quality. We use high-performance anti-corrosion coatings and spraying technology to ensure that the coating is uniform, has strong adhesion, and can effectively resist corrosion under various environmental conditions.

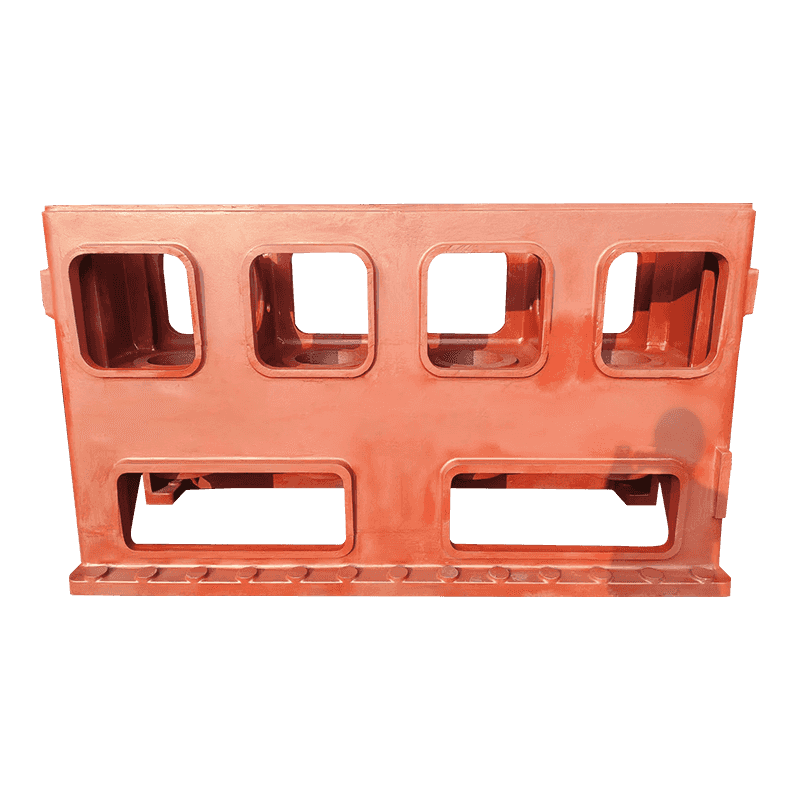

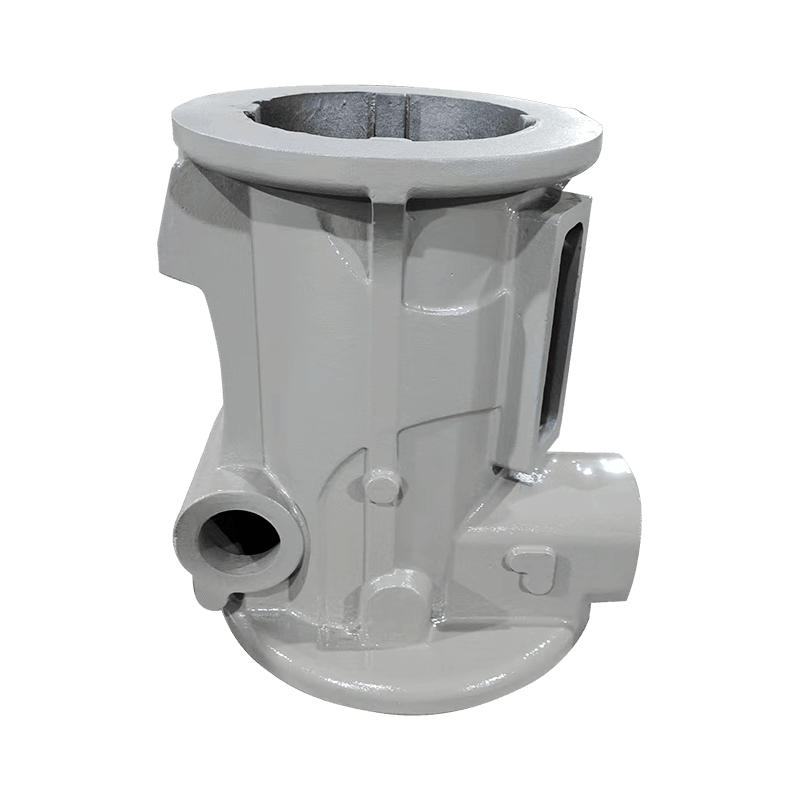

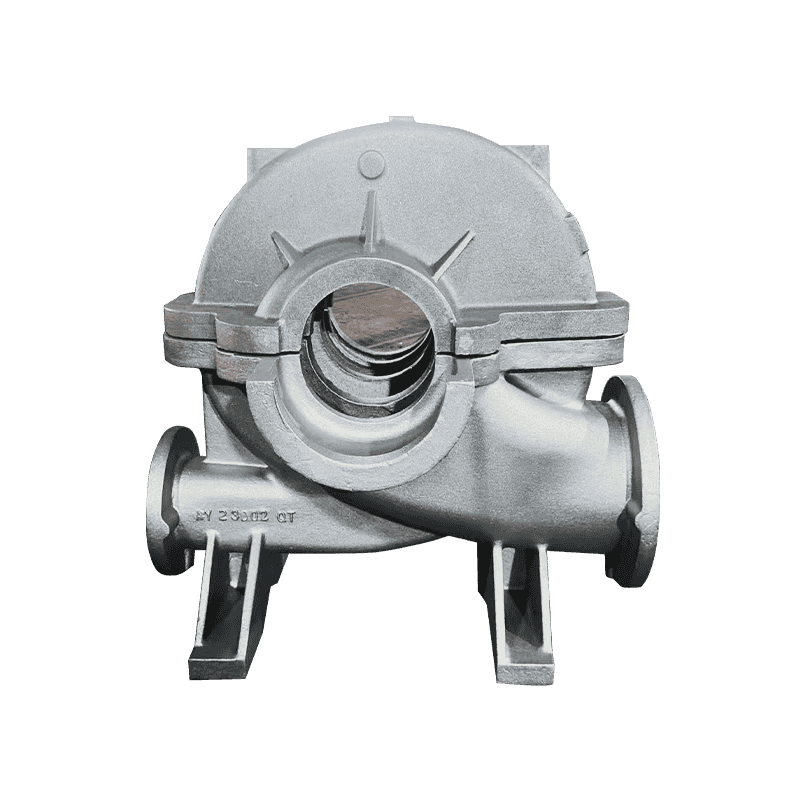

6. Machining

In order to ensure the dimensional accuracy and functionality of the Machine Base, Haian Aoyu Machinery Manufacturing Co., Ltd. also performs machining on the castings. Machining includes processes such as turning, milling, drilling and grinding. We use advanced CNC machine tools and processing equipment to precisely process castings according to customer drawing requirements. During the processing, we will strictly control the processing accuracy to ensure that every dimension and detail meets the specifications.

7. Quality Inspection

At every stage of the manufacturing process of the Machine Base, Haian Aoyu Machinery Manufacturing Co., Ltd. will conduct strict quality inspections. Including dimensional testing, mechanical property testing and material testing. We use advanced testing equipment and instruments to conduct comprehensive inspections on castings to ensure that they meet design requirements and quality standards. The quality assurance team will conduct a series of tests before and after casting to ensure the stability and reliability of the finished castings during use.

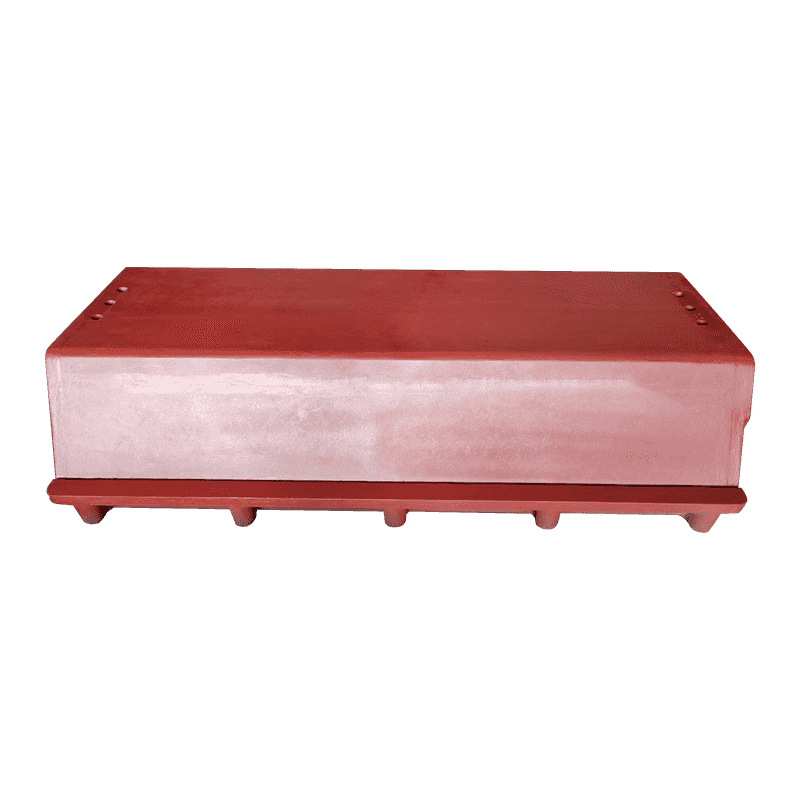

8. Final processing and delivery

After all the above processes, the Machine Base will undergo final inspection and processing. Haian Aoyu Machinery Manufacturing Co., Ltd. will clean the castings to remove residues generated during processing and coating. After the final inspection and confirmation, we will package and transport them. We will provide appropriate packaging solutions according to customer requirements to ensure that the castings are not damaged during transportation.

Haian Aoyu Machinery Manufacturing Co., Ltd. is committed to providing high-quality Machine Base products and guarantees product performance and reliability with strict manufacturing processes and quality control. From casting process design, mold production, casting production, heat treatment, coating, machining to final quality inspection and delivery, we strictly control every link to ensure that each Machine Base can meet customer needs and usage requirements. Our goal is to help customers achieve production goals and improve equipment performance and reliability through high-quality casting products and professional services.